Chevron Conveyor Belt

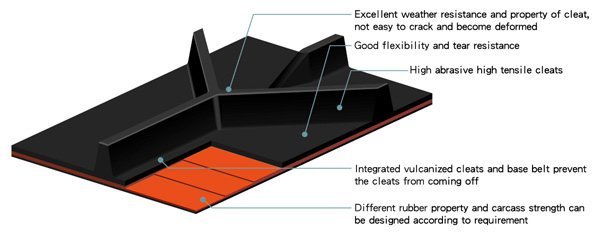

Characteristics

Carcasses include Polyester/Nylon (EP), Nylon/Nylon (NN), Cotton/Cotton (CC) and Steel Cord (ST)

- High Traction: Preventing material rollback on inclined conveyors.

Effective Conveying: Ideal for transporting bulk materials with varying sizes, such as sand, gravel, and packaged goods, even on steep inclines.

Smooth Material Flow: The patterned design helps maintain a consistent material flow, reducing the risk of spillage and ensuring efficient conveying.

Versatile Applications: Suitable for a wide range of industries, including mining, agriculture, construction, and recycling, where inclined conveying is essential.

Abrasion Resistance: Chevron belts are often engineered with high-quality materials, ensuring durability and resistance to abrasion, even in demanding environments

Flexible Design: Chevron conveyor belts come in a variety of patterns (V-shape, U-shape, etc.) and can be customized to match specific incline angles and material requirements.

Enhanced Safety: Chevron belts contribute to better material containment, reducing the likelihood of accidents and injuries caused by material spillage.

Reduced Maintenance: The patterned design minimizes belt slippage, leading to lower maintenance needs and longer belt life.

Easy to Install: Chevron belts can be installed on existing conveyor systems, making it a cost-effective solution for upgrading incline conveyors.

Resistance to Impact: Chevron conveyor belts are designed to handle material impact, making them suitable for applications where materials may fall onto the belt.

Applications

- Incline Conveying

- Bulk Material Handling

- Steep Terrain Conveyance

- Aggregates (e.g., Sand, Gravel)

- Mining Operations

- Wood Processing

- Textile Industry

- General Material Handling

- Airport Baggage Handling

- Manufacturing (Automotive, Electronics, etc.)

NB: Chevron conveyor belt’s patterns can be customized based on customer request and intended use. Please contact us for more information regarding this.